The role of the connector in production is the role of the connection, but what is the role of the connector in other industries? In the service industry, especially in the automotive repair industry, the connectors used will bring us very Great help, because in the process of repair, after using the connector, you don't have to worry about running other machines, there is no worry about repairing the contract, because the car is stopped for another part of the operation.

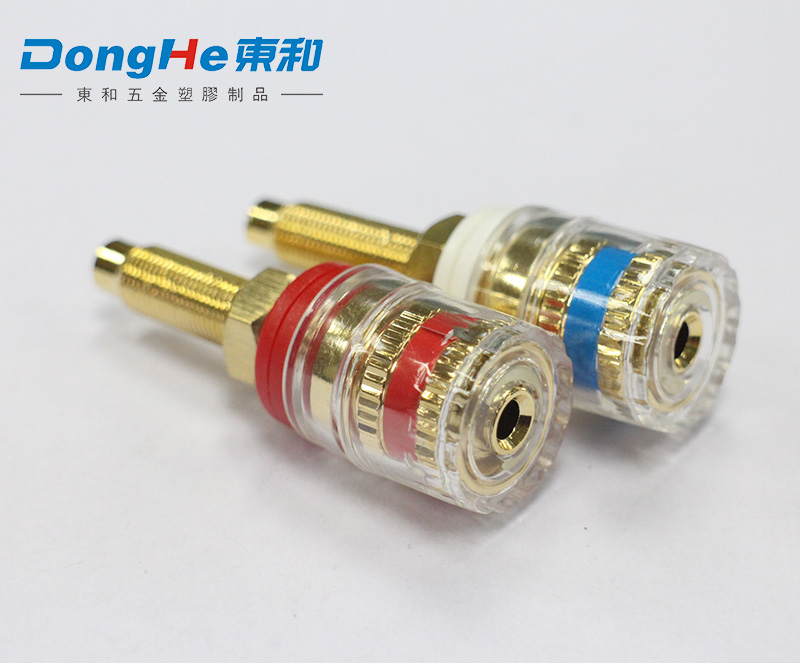

Another connector is another design that requires different shapes when it is used. Each shape of the connector will have its own application requirements. Of course, in actual use, we can also choose to use it. Some shapes are requested on the connector.

Connectors are always used in different industries, but the application in this process is different. The main function of the connector in production is to connect different production parts, where the role connector is a simple The connection, of course, these are exactly what we need to do.

(1) A heat-resistant current connector with a maximum operating temperature of 200 °C (with the exception of some special connectors) with a minimum temperature of 65 °C. Because of the current generated by the connector at the point of contact, which causes the temperature to rise, it is generally considered that the operating temperature should be equal to the sum of the ambient temperature and the junction temperature rise. In some specifications, the maximum temperature allowed for the connector specified in the rated power flow rises.

The role of the connector in production is the role of the connection, but what is the role of the connector in other industries? In the service industry, especially in the automotive repair industry, the connectors used will bring us very Great help